In recent years, changing global dynamics and market uncertainty have put many companies across various sectors under significant pressure, including our own, the stainless...

Internationalization, the drive of a company to seek new markets to serve, adapting to the standards, requirements, and specificities of new territories, has always been...

A company that controls its supply chain can effectively manage procurement, production, and logistics, expand its reach into new markets, diversify, and therefore grow and become more...

At Metal’s, we have been manufacturing semi-finished products and complex assemblies in stainless steel for the medical sector for many years. We have in-depth knowledge of the exacting specifications and standards...

We are excited to announce our participation in HOST Milano 2025, the international trade fair dedicated to hospitality and professional catering, taking place at...

Reducing costs. This has been the most frequent request we've received from our clients over the past year. For many industrial companies, reducing business costs has become essential to remain competitive in the market.

Containing production costs has become an increasingly widespread necessity among companies in the industrial sector. It’s a trend we observe every day at Metal’s.

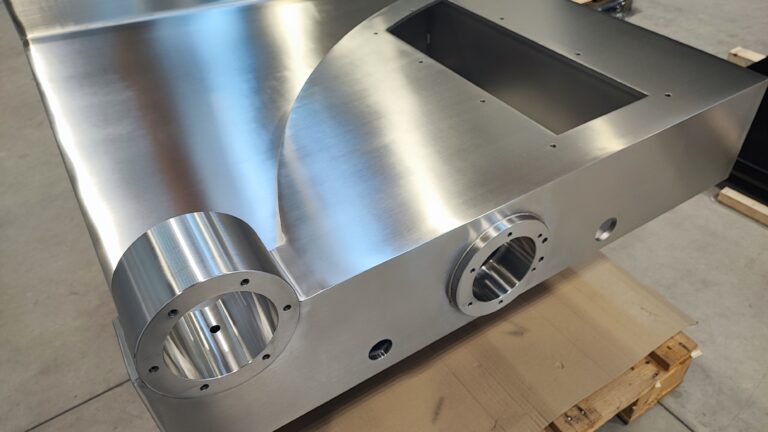

At Metal’s, we process stainless steel to create assemblies, semi-finished products, machine parts, and large-scale machinery for various markets. Above all, we offer a service that covers...

At Metal’s, we have enhanced our machinery fleet with robots and new equipment capable of efficiently managing the automation of finishing processes on large...

We are pleased to announce our participation as exhibitors at IFFA Frankfurt 2025, the international benchmark event for the entire meat and protein processing...

At Metal’s, we can enhance the design of a semi-finished product or a complex assembly to optimize production at fixed costs. By finding solutions tailored to...

Steel bending is a critical process in the production of semi-finished products and assemblies, allowing flat steel sheets to be…

When our sales department receives an order for the production of a complex assembly, the Metal’s machine is set in…

A few technical changes on a project that has already been agreed and started some time ago can improve the quality of an assembly or semi-finished product functionally, aesthetically and, last but not least, economically. Changes that...

Stainless steel stamping is a process that allows the metal to be shaped into a specific form. It is possible…

At Metal's we can carry out orders with certified welding, to meet the specific needs of our customers. In fact, we have a large fleet of machines, complete with...

Increasing the service life of complex stainless steel fabrications and assemblies is an important option for those who want to offer high quality products capable of being...

The environment is a topic close to our hearts. That’s why in 2024 at Metal’s we have decided to expand…