Increasing the longevity of products and complex assemblies made from stainless steel is crucial for those aiming to offer high-quality products that withstand wear and time.

Steel is composed of varying amounts of metals such as iron and carbon, in addition to nickel and chromium. Chromium, in particular, creates a protective layer (also known as the “passive layer”), which is essential against corrosion. Despite stainless steel being a durable material that does not deteriorate easily, improper maintenance, incorrect cleaning, or an accident can damage the passive layer, ruin the surface, and lead to rust, stains, and even oxidation.

Therefore, it is ideal to act in two phases. The first is preventive, by scheduling one or more targeted and specific treatments during production based on the final use of the product. The second phase concerns post-sales. In this case, the end customer must take care of the stainless steel surface by always performing proper maintenance to make it last longer.

Throughout this article, we will understand the different possibilities for increasing the longevity of stainless steel. Let’s explore them together.

What can compromise the longevity of stainless steel?

Before answering this question, it is important to highlight that stainless steel is an alloy that is:

- durable;

- lightweight;

- easy to clean;

- low maintenance;

- highly bacteria-resistant.

These characteristics make it an excellent option for producing high-quality stainless steel products and complex assemblies for various sectors, from the food industry to the pharmaceutical industry.

But how can such a durable alloy be compromised? Various factors can affect its robustness and damage the protective layer. Specifically, there are four different situations to consider:

- Chemical contamination: Occurs when certain substances (found in chemical products like chlorides, for example, or through contact with saltwater) damage the protective shield of stainless steel, making it susceptible to corrosion.

- Ferrous contamination: Occurs due to contamination with iron. Iron particles present on a surface or tool can deposit on the stainless steel, triggering galvanic corrosion.

- Temperature and pollution: High temperatures can affect the quality of the metal and create darker areas on the outermost layer. Additionally, polluted air can contain substances that damage the protective layer and initiate corrosion.

- Scratches and damages: During maintenance and cleaning, it is always advisable to use suitable products and materials to avoid scratching the protection provided by chromium.

Treatments to increase the longevity of stainless steel

To prolong the life of products and complex assemblies made with stainless steel, specific treatments can be considered to enhance stainless steel resistance and integrity.

Depending on various needs, different surface treatments for steel can be chosen, such as:

surface treatments of steel come:- Galvanization: To protect metals from galvanic corrosion.

- Metallization: To add a layer of material (and extra protection).

- Anti-corrosion coatings and painting: To improve the resistance and robustness of the alloy with specific treatments and products.

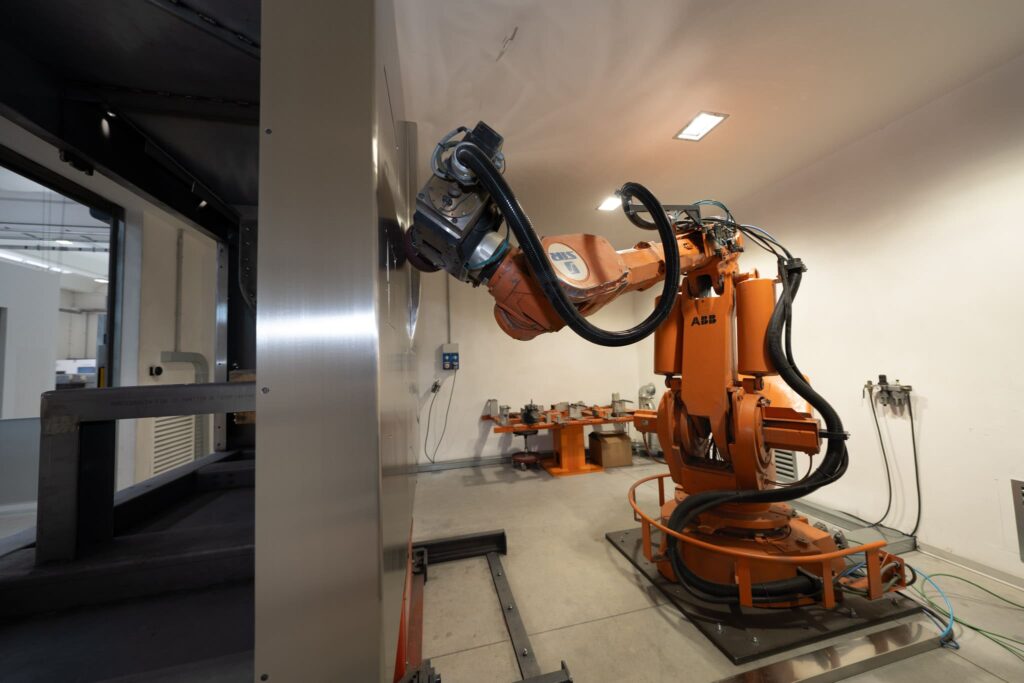

At Metal’s, we can perform localized treatments that maintain the surface characteristics of the steel, which would otherwise be susceptible to erosion. However, these processes are carried out only upon explicit customer request or if required by law. For example, there are specific application sectors, such as the food and medical fields, where certain treatments – like galvanization and pickling by immersion (a localized electrochemical process) – are mandated by regulations.

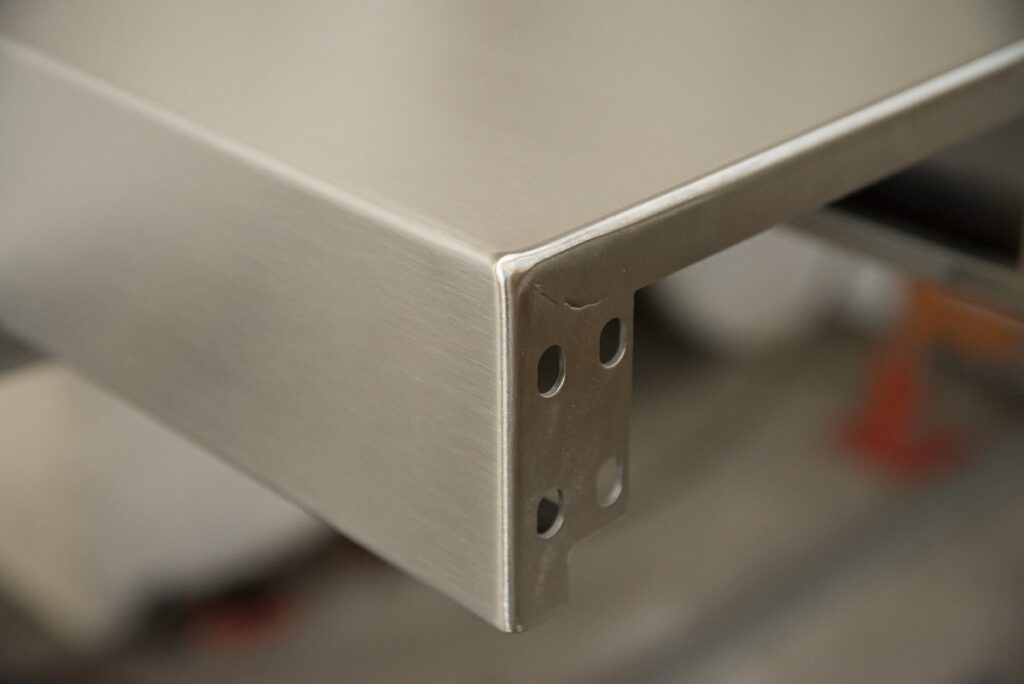

In particular, complex assemblies designed for the HORECA sector require both brushing and pickling. For example, slicer welds for deli counters need cleaning and pickling in visible areas. However, the customer can request additional product assurance by pickling even the non-visible areas.

The benefits of stainless steel treatments

Whether required by law or requested by the customer, surface treatments on stainless steel offer numerous benefits. Besides increasing durability and resistance to corrosion and oxidation, they help to:

- uniform the surface;

- improve the aesthetics of the product;

- eliminate imperfections, shadows, and other marks;

- remove impurities.

The importance of routine maintenance to increase stainless steel longevity

Surface treatments on stainless steel are a crucial preventive phase that can extend the life of the stainless steel and the product.

The essential step is to always start with a good base product by evaluating only high-quality types of stainless steel. Once the product is manufactured and sold to the end customer, are there still measures to take to prevent potential damage?

Certainly, regular routine maintenance of the product is fundamental, inspecting the product periodically to detect any imperfections, signs of rust, or indications of corrosion. This allows for timely intervention before the material suffers more severe damage.

Additionally, regular deep cleaning of stainless steel surfaces is advisable, which may vary depending on the destination sector (i.e., with specific products and more or less frequent schedules). The recommendation is to use only non-abrasive cleaners and soft cloths to keep the metal surface intact, avoiding scratches as much as possible. It is also crucial to protect stainless steel from contact with corrosive substances (such as chlorides and aggressive chemicals) that can damage it and undermine its resistance and durability.

Do you want to know more?

Do you want to increase the longevity of your complex stainless steel assemblies and products? Discover how we can assist you: rely on our professionals and evaluate the benefits you can obtain for your processes.