Supply chain control and market diversification at Metal’s

Un’azienda che ha il controllo della supply chain può governare approvvigionamenti, produzione e logistica, estendere il proprio raggio d’azione verso altri mercati, diversificarli e quindi crescere e strutturarsi. L’obiettivo è ottimizzare e rendere più efficienti le attività, affrontare con più sicurezza le fluttuazioni del mercato, costruire know-how e metterlo al servizio dei clienti dello stesso […]

Come visit us at HOST Milano 2025!

Siamo entusiasti di annunciare la nostra partecipazione a HOST Milano 2025, la fiera internazionale dedicata al mondo dell’ospitalità e della ristorazione professionale, in programma a Fiera Milano Rho dal 17 al 21 ottobre 2025. Dove trovarci:Padiglione 5P – Stand R11 S12 Ti aspettiamo per scoprire insieme tutte le nostre novità e soluzioni innovative, pensate per […]

Case history: reduction of production and price list costs for two long-standing Metal’s clients

Contenere i costi di produzione è diventata un’esigenza sempre più diffusa tra le aziende del settore industriale. È una tendenza che vediamo ogni giorno anche in Metal’s. A causa delle contrazioni del mercato, molti clienti ci chiedono sempre più spesso di ridurre i costi di produzione, senza compromettere la qualità e l’affidabilità dei prodotti forniti […]

Metal’s, beyond stainless steel processing: a service covering the entire logistics process

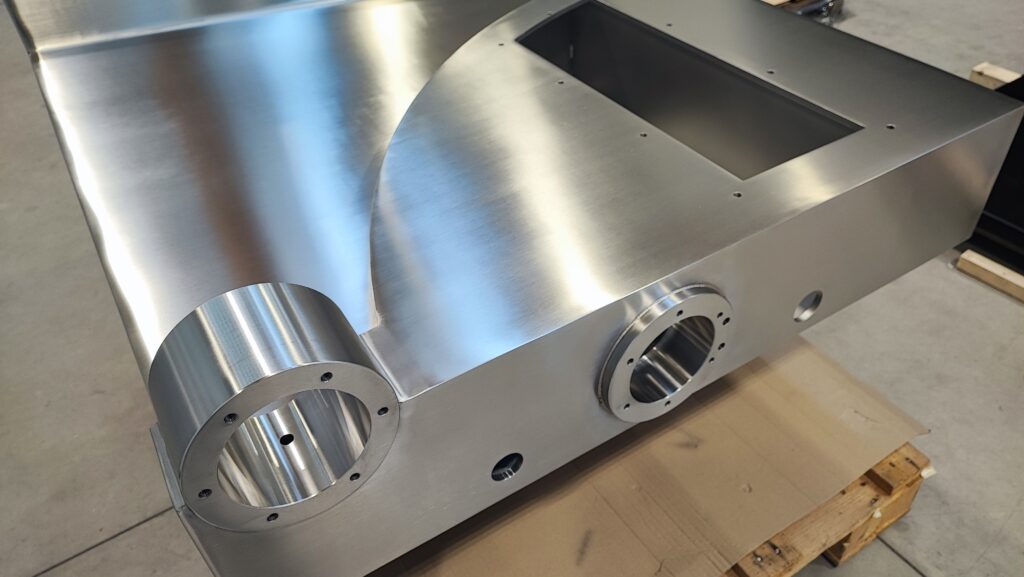

In Metal’s lavoriamo l’acciaio inox per realizzare assiemi, semilavorati, parti di macchine e grandi macchinari destinati a diversi mercati. Soprattutto, forniamo un servizio che copre l’intero processo logistico, perché abbiamo scelto di non essere semplici fornitori per i nostri clienti, ma un partner specializzato nella realizzazione di soluzioni tecnologicamente elevatissime. In questo articolo, ti raccontiamo […]

Automation of finishing processes for large machine parts: the Metal’s example

In Metal’s abbiamo implementato il nostro parco macchine con robot e nuovi macchinari capaci di gestire al meglio le automatizzazioni delle finiture su semilavorati di grandi dimensioni. Così facendo, possiamo fornire ai nostri clienti un servizio e un prodotto sempre più completi, centralizzando e automatizzando le lavorazioni e limitando le collaborazioni con partner esterni. Il […]

We’ll be attending IFFA 2025: the world’s leading trade fair for the meat and protein industry

Siamo lieti di annunciare che parteciperemo come espositori a IFFA Frankfurt 2025, l’evento internazionale di riferimento per l’intera filiera della lavorazione e trasformazione delle carni e delle proteine, in programma dal 3 all’8 maggio 2025 presso il centro fieristico di Francoforte. 📍 Ci trovate allo Stand A30 | Hall 11.0 La nostra presenza a IFFA […]

Caged nuts and other modifications to optimize production at fixed costs: A Metal’s case history

In Metal’s possiamo migliorare il progetto di un semilavorato o di un assieme complesso per ottimizzare la produzione a costi certi. Trovare soluzioni adeguate alle esigenze dei committenti, consigliando loro miglioramenti specifici, consente di ridurre la marginalità di errore e realizzare prodotti di alto livello, già pronti all’uso o da assemblare. In Metal’s il nostro […]

Steel bending: a high-precision process

La piegatura dell’acciaio è un processo chiave nell’ambito della produzione di semilavorati e assiemi perché consente di attribuire una forma – anche complessa – a una lastra di acciaio piatto, senza alterarne le proprietà meccaniche. In questo articolo vedremo meglio di cosa si tratta, le sue caratteristiche, i vantaggi, le diverse tipologie di piegatura e i macchinari […]

Metal’s for complex stainless steel assemblies: the supply of systems in an advanced state of assembly

Quando il nostro ufficio commerciale riceve una commessa per la realizzazione di un assieme complesso, la macchina di Metal’s si mette in moto per rispettare le richieste e le tempistiche concordate con i nostri clienti. Come funziona questo processo, quali parti coinvolge attivamente e quali sono i vantaggi per chi si rivolge a noi? L’acquisto […]

Metal’s case history: technical modifications to improve project performance

Alcune modifiche tecniche su un progetto già concordato e avviato da tempo possono migliorare la qualità di un assieme o un semilavorato a livello funzionale, estetico e, non da ultimo, economico. Cambiamenti che coincidono spesso con l’arrivo di nuove tecnologie, sempre più all’avanguardia e performanti. Quando il parco macchine di Metal’s si arricchisce di una nuova apparecchiatura funzionale al progetto, il nostro ufficio tecnico valuta eventuali implementazioni al […]

Deformation through stainless steel stamping: what it is and how to use it in your projects

Lo stampaggio dell’acciaio inox è una lavorazione che consente di dare una forma particolare al metallo. Si possono realizzare profili geometrici, anche complessi, senza eccessivi sprechi di materiale, mantenendo invariate tutte le preziose caratteristiche dell’acciaio inossidabile. Per effettuare lo stampaggio servono macchinari all’avanguardia, oltre a una profonda conoscenza del metallo e della sua lavorazione, valutando – caso per caso – […]

Case history Metal’s: welding, an ISO 3834-2 certified automated process

In Metal’s possiamo eseguire commesse con saldatura certificata, per soddisfare le esigenze specifiche dei nostri clienti. Disponiamo, infatti, di un ampio parco macchine, completo di sistemi automatizzati che ci consentono di certificare determinate lavorazioni, oltre a migliorare la produzione e velocizzare le operazioni per rispettare sempre le tempistiche concordate. Ponendoci come unico referente, possiamo curare […]

Stainless steel in products: how to increase its longevity

Aumentare la durata dei manufatti e degli assiemi complessi realizzati in acciaio inox è un’opzione importante per chi vuole offrire prodotti di alta qualità, capaci di resistere all’usura e al tempo. L’acciaio, infatti, è composto da una quantità variabile di metalli come il ferro e il carbonio, oltre al nichel e al cromo. Quest’ultimo, in […]

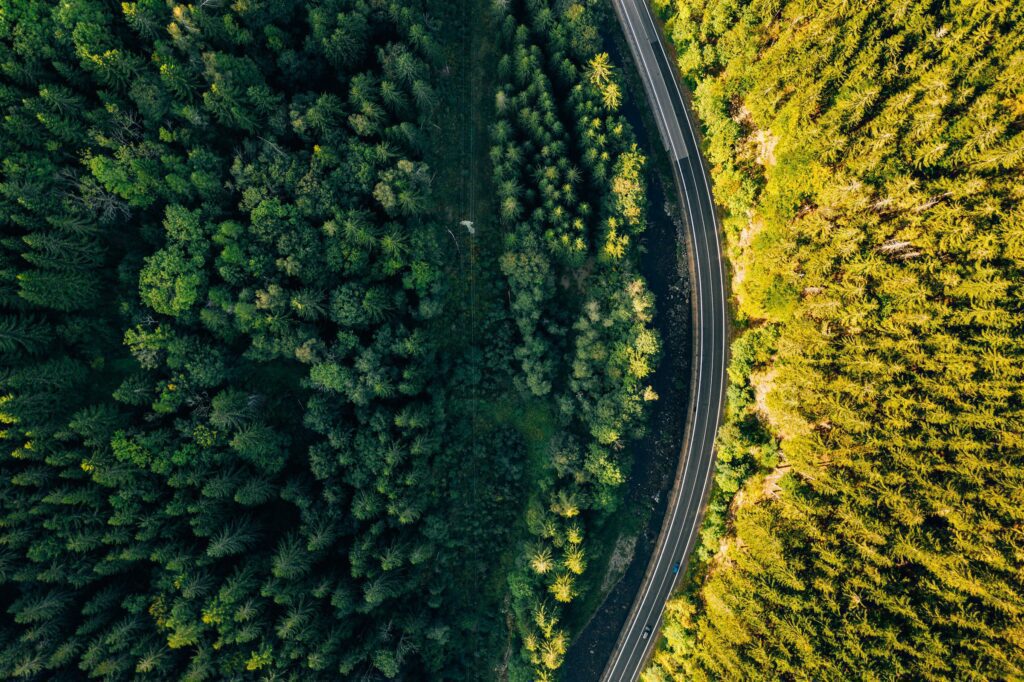

Metal’s ecological footprint and the next steps for the environment

L’ambiente è un tema che ci sta a cuore. Ecco perché nel 2024 in Metal’s abbiamo deciso di ampliare la nostra Green Mission, avviando due nuovi progetti per la sostenibilità: Propositi ambiziosi, che abbiamo delineato in dettaglio nel corso della presentazione del piano biennale per lo sviluppo sostenibile, e che ci serviranno per offrire ai […]

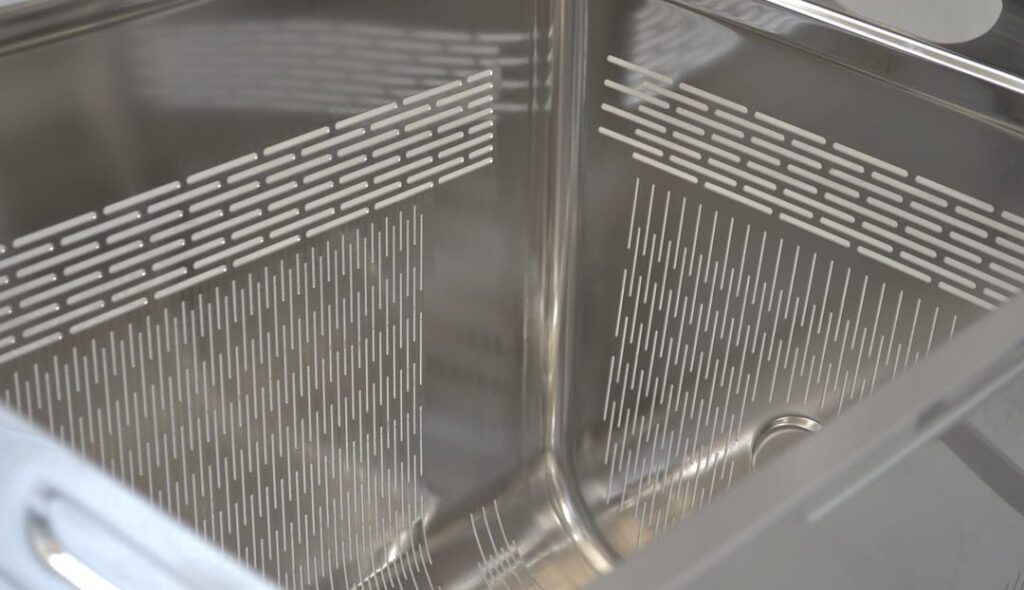

Food-Grade Stainless Steel: What Types?

Quando si parla di acciaio inox alimentare si fa riferimento a una particolare lega di acciaio inossidabile utilizzata nell’industria del beverage e food. Viene impiegata soprattutto in questo ambito perché evita le contaminazioni e offre altri importanti vantaggi. Ma quante tipologie di acciaio inox alimentare esistono, quali sono le sue caratteristiche e come si distinguono […]

Metal’s commitment: a biennial plan for sustainable development

In Metal’s l’impegno per la sostenibilità e l’ambiente è all’ordine del giorno anche per tutto il 2024. Il rispetto per il pianeta – e la comunità in cui operiamo – è una tematica a cui teniamo molto e sono diversi i progetti che intendiamo realizzare per sviluppare ulteriormente la nostra Green Mission. Del resto, negli […]

Metal’s case study: how we improved production with automated processing

In Metal’s realizziamo assiemi, semilavorati, parti e componenti in acciaio inox, sia semplici che complessi. Lavoriamo l’acciaio, ma ci occupiamo anche della fase progettuale e tecnica, consigliando ai nostri clienti alcune migliorie per ottimizzare i tempi di lavorazione o ridurre i costi di produzione, ovviamente senza ripercussioni sulla qualità. Il nostro è un lavoro ricco […]

On the way to Internorga

Siamo felici di annunciare che a partire da domani parteciperemo alla Fiera Internazionale Internorga ad Amburgo! Internorga è il punto di incontro per eccellenza del settore dell’ospitalità e del food, riunisce innovatori, esperti e appassionati da tutto il mondo.Dal 8 marzo al 12 marzo, vi aspettiamo presso il Padiglione B7, Stand 516.Sarà un’ottima opportunità per […]