How does this process work? What parts are actively involved, and what benefits do our clients gain by working with us?

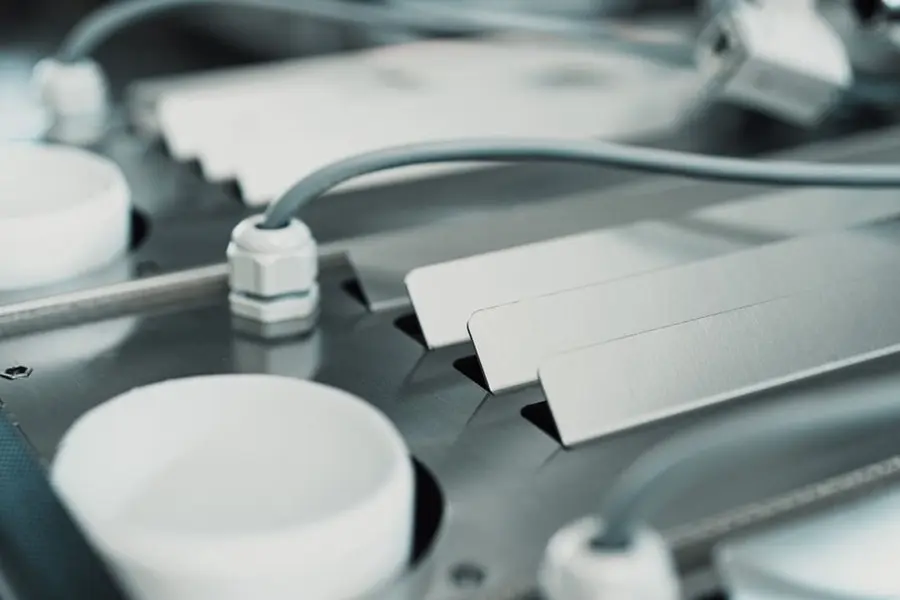

From the procurement of raw materials—primarily stainless steel—to order management, inventory control, logistics, and shipping, the coordination of each phase is crucial. Partnering with Metal’s means working with a single provider that streamlines complex and specialized supply chains.

In this article, we will detail how we handle raw material sourcing, categorize materials before production, and utilize cutting-edge technologies throughout the process. This approach allows us to deliver the complex assemblies co-designed with our clients on schedule. Additionally, we’ll explore the role of the supply chain and explain why it has become increasingly important for our company.

Material sourcing: stainless steel

In a previous article, we explained how we work at Metal’s and how our production process unfolds. In this follow-up, we will focus on the material sourcing phase, which, in our case, primarily involves the procurement of stainless steel.

The main types of stainless steel we use for our production are:

- AISI 304: With chromium content (between 18% and 20%) and nickel content (between 8% and 11%), this is a high-quality material, highly resistant to corrosion yet easy to work with. It is recommended for products used in the storage of substances in the food industry and for chemical applications.

- AISI 430: A ferritic stainless steel that is resistant to high temperatures.

- AISI 316: A standard stainless steel with varying percentages of chromium (between 16% and 18%), nickel (between 11% and 14%), and molybdenum (between 2% and 3%). Known for its high resistance to corrosion, it is used in the pharmaceutical, chemical, and food industries.

The material is sourced from the most reputable European steel mills, which can supply flat-rolled sheets that are already cut to a specific format, whether standard or customized. Of course, we can also obtain other types of stainless steel to best meet our clients’ needs.

Precise orders and careful inspections upon receipt of goods

Once the most suitable type of stainless steel has been determined with the client for the development of a complex assembly project in an advanced stage of assembly, we enter the order into our management system and send it to the supplier.

The order is accompanied by drawings, all relevant specifications, and a technical supply specification document. This detailed document outlines the material requirements for the supplier, including both technical (such as dimensions and thickness) and aesthetic (such as finish and roughness) specifications. It also specifies the packaging requirements. This is a crucial detail, as all our plants are equipped with automatic loading systems, and an incorrect evaluation can delay production.

Upon receipt of the materials, warehouse team must verify their suitability and check the accompanying documentation, ensuring that the information matches the ordered product and is consistent.

It’s important to note that each delivery is always accompanied by a 3.1 certificate (as required by EN 10204 regulations), which identifies the casting origin of the individual material. This certificate includes all the chemical characteristics of the stainless steel and is vital for the verification and processing stages.

If everything is in order, the material is labeled and stored in the warehouse, ready to be used.

The importance of labeling

Labeling raw materials is crucial because the unique code identifies both the supplier’s batch and our finished product. This allows us to trace the material at any point, even after the complex assembly has been delivered to our clients.

This is an added value for those who rely on Metal’s because, in the event of non-compliance reports or requests for specific information such as product traceability (for example, for medical sector products), we can always trace back to the material used in the production of each item.

With an advanced management system, every flow is always under control

At Metal’s, we leverage the best technologies for order and production flow management. As previously mentioned, the order is sent to suppliers via our management system. This method allows us to streamline the automatic procurement of materials and share important documents such as drawings, checklists, and specifications.

Our ERP system is connected to all areas of Metal’s, from administration to the warehouse, and in real-time, it provides an accurate snapshot of inventory and material usage for each specific project. Thanks to an advanced feature (the MRP algorithm), the system analyzes the needs related to sales orders and generates purchase or production requests.

Depending on the type of item and the agreements with the customer, items are automatically ordered by the system to prevent production delays and address potential shortages of raw materials. Naturally, all items are managed with different procurement policies, and stock levels, production batches, and lead times are manually entered to ensure agreed-upon delivery dates.

Moreover, to ensure quick responses to market demands, Metal’s uses an inventory management system known as consignment stock. This means that, in agreement with our suppliers, we keep a specific quantity of stainless steel in our warehouses that will only be used if necessary. The advantage? Always having a supply of raw materials, ensuring a smooth workflow.

An integrated and shared system

At Metal’s, we have chosen an ERP (Enterprise Resource Planning) software that aligns with the Industry 4.0 production paradigm and is always interconnected with our state-of-the-art machinery.

The ERP is natively integrated with all systems for MES (Manufacturing Execution System), WMS (Warehouse Management System), and TQM (Total Quality Management). This ensures that information is accessible and easily monitored in real-time at all company levels.

In detail:

- MES (Manufacturing Execution System) tracks the progress of production orders, records real-time timings, and shares all necessary documentation.

- WMS (Warehouse Management System) ensures accurate material management, determining the location of items within the company and managing inventory levels.

- TQM (Total Quality Management) analyzes potential process deviations in real-time and ensures the achievement of pre-established PPM (Parts Per Million) standards set by the market or internal production.

What happens when the order includes materials other than stainless steel?

For some clients, we create complex assemblies that involve combining stainless steel with other materials. When sourcing raw materials, we can follow two solutions:

- Relying on our trusted Italian and international suppliers;

- Contacting trusted partners recommended by our clients.

In the first case, we can request a quote and acquire the necessary components at favorable prices and/or with better delivery conditions. If the terms meet our clients’ expectations, we proceed with the order.

Of course, upon the client’s request, we can intervene at any stage. For example, during production, we can seek a more cost-effective supplier to optimize costs without compromising product quality, or in case of an emergency, when a component needs to be replaced or is no longer available.

In a fast-paced and constantly evolving market, having a single, technically prepared point of contact for procurement—someone capable of adapting to ever-changing requirements—represents a crucial competitive advantage.

A solution for large-scale complex assemblies

We have expanded our facility with a new mechanical division specialized in the production of large-scale complex assemblies. This automated system, enhanced with specific machinery such as milling machines, allows us to work with maximum precision even on small batches.

This enables us to take on new challenges, both within the Italian market and internationally, from Europe to America. We can offer an increasingly complete product to our clients—also in terms of aesthetic finishes—while meeting the requirements set out in the project.

Outsourcing activity management is also digital

We have implemented an SCC portal to manage the outsourcing supply chain in an integrated way for activities that require external suppliers’ support, such as painting or electropolishing. In this way, orders generated by the management system are directed to the portal, which is always accessible to the supplier.

This tool is easy to manage and consult, where:

- Orders are recorded (including drawings and all relevant information);

- Production progress can be tracked;

- Labels necessary for delivery and identification of goods can be generated.

By using this system, we minimize communication and avoid information loss, optimizing production timelines.

The role of the supply chain in supplying advanced pre-assembled systems

A calculated management of the company’s supply chain enables us to coordinate and optimize all stages of the production process, from sourcing to distribution.

To stand out in an increasingly competitive market, high-quality products must be delivered within the agreed deadlines, while reducing wait times, waste, costs, and preventing production interruptions due to unforeseen events. Therefore, it becomes crucial to:

- Coordinate relationships with multiple partners and raw material suppliers;

- Offer diversified processing and comprehensive logistics plans, ensuring that shipping—from packaging to delivery—meets all requirements and regulations of the destination.

At Metal’s, we manage the entire supply chain, positioning ourselves as the single point of contact for companies seeking a complete service, from sourcing raw materials to dispatching orders, with tailor-made solutions for various industrial sectors. By doing so, clients can focus on their core activities, leaving the entire production and logistics coordination to our specialists.

Want to learn more?

The production of complex stainless steel assemblies involves not only the purchase of raw materials but also their processing and shipment. Discover how we manage the entire process without delays and the benefits you can gain by choosing Metal’s as your sole point of contact.