When talking about food-grade stainless steel, we refer to a particular alloy of stainless steel used in the beverage and food industry. It is primarily employed in this field because it prevents contamination and offers other significant advantages. But how many types of food-grade stainless steel exist, what are their characteristics, and how do they differ from other materials? In this article, we will answer all these questions.

Food-grade stainless steel: how to recognize it

Various types of stainless steel are available on the market, each suitable for specific industrial processes. In particular, the Centro Inox (Italian Association for the Development of Stainless Steels) identifies two major families:

- Martensitic Stainless Steel: Durable, but with modest corrosion resistance (recommended for fasteners, cutting tools, and various machinery);

- Austenitic Stainless Steel: Versatile, heat, and corrosion-resistant (used in the food and medical fields, such as for making stovetops);

Within these broad categories, there are further types of stainless steel that differ in their characteristics and specific properties. To recognize them, the AISI (American Iron and Steel Institute) designation, a nomenclature composed of three digits, is used. Specifically, the first digit determines the class of resistance, and the remaining digits indicate the materials used in the alloy.

Why this classification is necessary? This subdivision is necessary because not all stainless steel is the same. Each variety is characterized by specific properties that make it perfect for certain uses. Additionally, some industrial sectors, such as the food industry, must meet specific requirements. Let’s explore what these are in more detail.

The best types of food-grade stainless steel

When referring to the food and beverage sector, we talk about food-grade stainless steel, a colloquial term used to identify all materials that meet the very high hygiene standards required for these processes. Specifically, two alloys are used in this sector: AISI 316 and AISI 304. Here are the main characteristics and differences.

Food-grade stainless steel AISI 316

AISI 316 is an austenitic stainless steel that contains molybdenum, a transition metal that, when combined with steel, increases its hardenability, hardness, mechanical strength at high temperatures, and corrosion resistance (even when using acids and chlorides such as salt). It is a highly valuable material and withstands temperatures significantly higher than those required during food preparation.

Food-grade stainless steel AISI 304

AISI 304 refers to a stainless steel characterized by a chromium content ranging from 18% to 20% and a nickel content between 8% and 11%. Cheaper than AISI 316, it is often used in the food and beverage sector because it is compatible with most food products (it is better to avoid very acidic and corrosive ones). Additionally, it is notable for its resistance and its ability to withstand both high and low temperatures.

Are there differences between stainless steel and other types of steel?

What distinguishes stainless steel from other types of steel is the presence of chromium. Specifically, to be classified as stainless steel, it must contain at least 10.5% of this valuable chemical element. Its characteristic? Chromium creates a thin, transparent protective layer that enhances the stainless steel’s resistance compared to other steels available on the market.

This is why stainless steel is a more:

- tough;

- lightweight and easy to work with (even with laser technologies);

- corrosion-resistant;

- heat-resistant;

- easy to clean and requires low maintenance (capable of ensuring the necessary hygiene for those working daily in the food sector).

Moreover, it does not require additional protective coatings (essential for some steel materials) and has high bacterial removability, preventing and avoiding food contamination through contact with the material.

How to choose the right food-grade stainless steel?

As we have seen, stainless steel is the best alloy for food processing. However, choosing the most suitable type depends entirely on your needs and the final use of the product. Therefore, it is necessary to evaluate, between AISI 316 and 304 stainless steels, which one meets all the necessary requirements. This includes considering the chemical composition of the food (paying attention to potentially corrosive elements) and the temperatures required during heating or refrigeration.

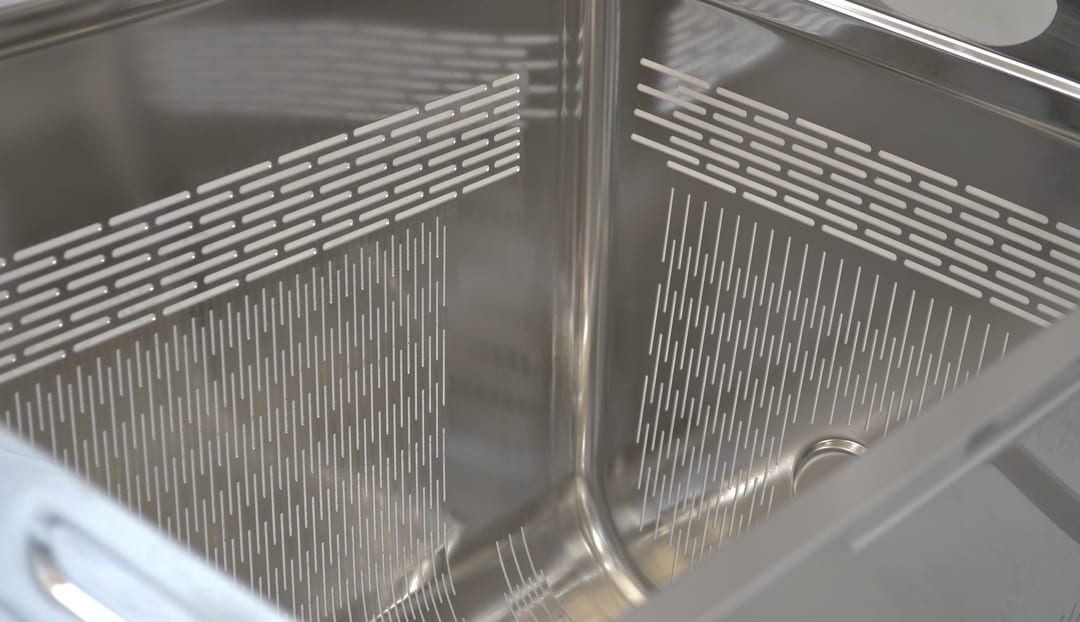

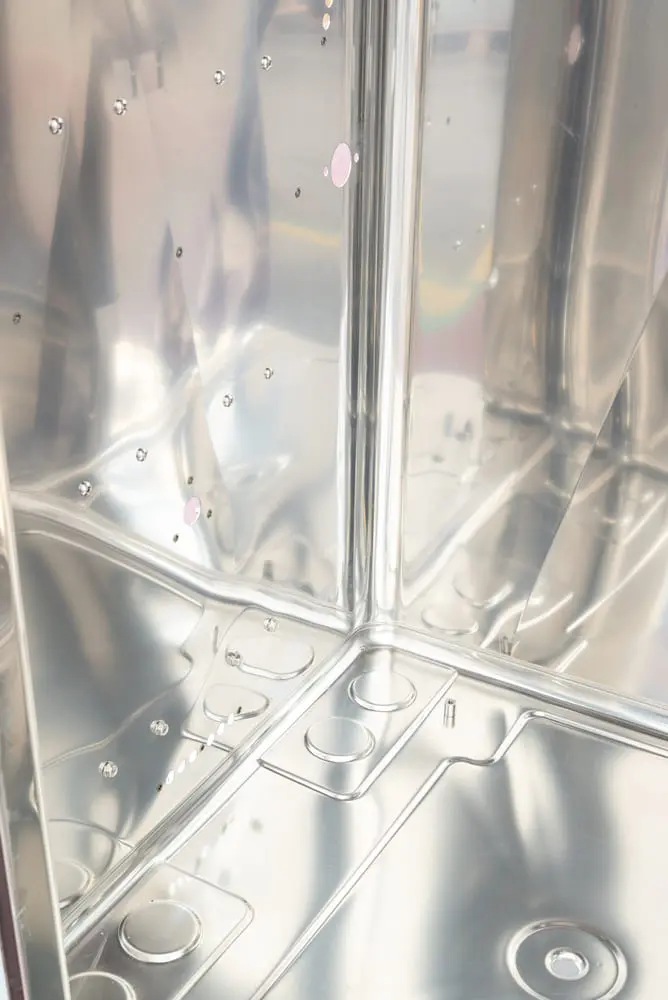

Regarding processing, at Metal’s, we have a constantly updated and state-of-the-art machine park that allows us to successfully complete any project, satisfying all functional, aesthetic, cost, and quality objectives set by the customer. Additionally, we specialize in particular processes such as brushing, essential for eliminating scratches and preserving the hygiene of the material.

At Metal’s, we specialize in processing stainless steel, including food-grade stainless steel. We have chosen to work exclusively with stainless steel to avoid contamination from foreign metals and to offer products that are safe for all food markets. Moreover, when projects involve working with different materials, we operate in separate processing environments to prevent any compromise of the stainless steel’s integrity.

Would you like to know more?

Discover how we can assist you in processing food-grade stainless steel. Trust our professionals and evaluate the benefits you can achieve for your operations.