Shot peening and satin finishing are two of the most commonly used surface treatments for refining stainless steel surfaces.

But what goals do they allow to achieve, and how do the two processes differ? In this article, we will explore the advantages, common characteristics, and differences between the two methodologies, as well as how to use them effectively.

What are the surface treatments of stainless steel and what are they used for?

Various surface treatments can be applied to stainless steel. These processes are typically carried out after manufacturing, with either aesthetic or functional purposes. They are useful, for example, in removing scratches or enhancing the material’s resistance.

Among the well-known surface treatments for stainless steel, we can mention:

- brushing to smooth the surface;

- electropolishing: providing a shiny, brilliant surface and reducing roughness;

In addition to these, we’ll delve into stainless steel shot peening and satin finishing in the following paragraphs.

What is stainless steel shot peening and how it is done

As reported in the study “Effect of shot peening on the hardening and surface roughness of nitrided austenitic stainless steel”, published in the International Journal of Engineering Science and Technology, shot peening is a treatment that enhances not only the material’s aesthetics but also renews its robustness and extends its life.

Following all processes – such as cutting, welding, punching… – stainless steel undergoes significant changes in its structure, which tends to lose strength and resistance.

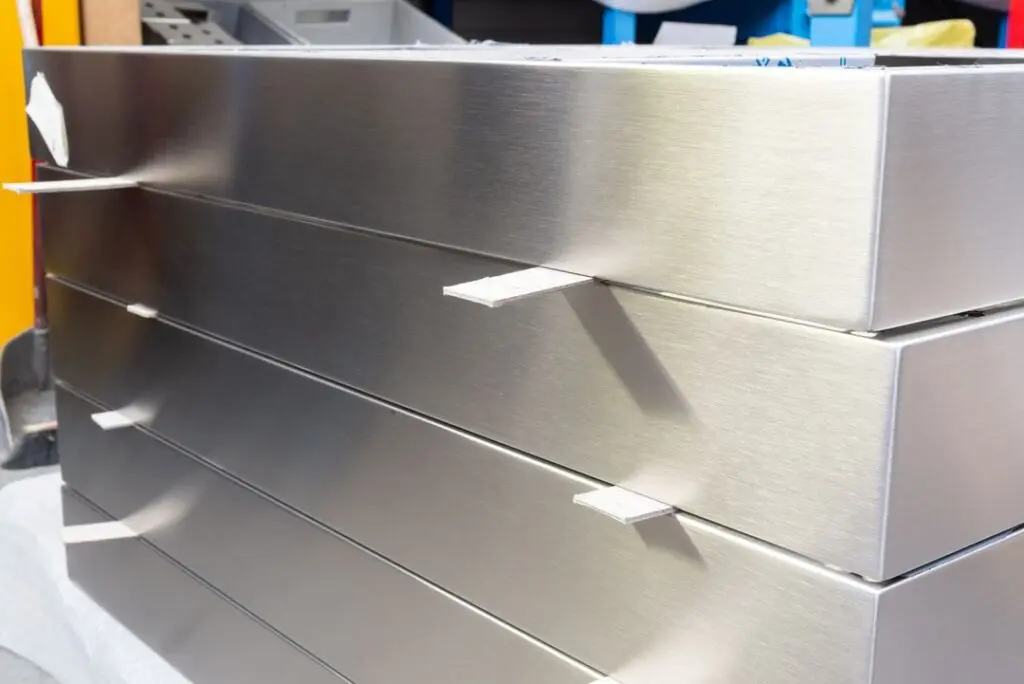

The shot peening process takes place in the final stages of production and is entrusted to specific machinery where stainless steel is literally bombarded by thousands of spheres (made of glass, steel, ceramic) across its entire surface.

This process occurs at high speed. The compressed air jet – controlled at every step – pushes the beads against the area to be treated, ensuring a better distribution of tension throughout the material and increasing its solidity without damaging the surface. In fact, the process creates small craters on the stainless steel’s surface layer, inducing metal compression, making it more resistant and durable.

Additionally, this treatment also impacts the aesthetics of the steel. Shot peening, indeed, eliminates imperfections and scratches, improves material adhesion, and roughness, preparing the material for subsequent processes, such as painting, for example.

Shot peening and micropowder peening of stainless steel: features and benefits

Shot peening and micropowder peening are two treatments that are practically identical, differing primarily in the size of the spheres used in the process. Micropowder peening, in particular, is recommended for the processing of high-quality and delicate components.

Depending on the desired finish, the abrasive material of the spheres (such as ceramic, glass, stainless steel) and their size can be selected to recreate a uniform, matte, non-reflective, and highly homogeneous surface.

The shot peening or micropowder peening process is, therefore, recommended for:

- increasing the durability of the material;

- improving the strength of stainless steel after processing;

- uniformizing the surface;

- eliminating oxidation, welding traces, and imperfections.

Satin finishing of stainless steel: What is its purpose?

Satin finishing, on the other hand, is a treatment primarily focused on the aesthetic aspect of a stainless steel product. In this case as well, the process occurs on the material’s surface to be worked on, but it involves the use of abrasive belts to eliminate imperfections and scratches. Moreover, the belts can have different grains and formats depending on the desired result.

The satin finishing process is delicate and rather complex: the treatment must be uniform, carried out with great precision, and using cutting-edge machinery to perfectly address defects caused by previous processes (such as bending and welding).

The advantages of satin finishing can be summarized as follows:

- Eliminates imperfections resulting from stainless steel processing (such as burrs, oxidation, and scratches).

- Gives the metal a matt appearance, making it aesthetically more appealing.

- Removes the reflection on the surface, making it opaque (useful in certain markets, such as the food and packaging industry, for example).

- Prepares stainless steel for further surface treatments or coatings.

Why consider shot-peened steel?

As we have seen, satin finishing and shot peening are two crucial surface treatments for stainless steel, especially for those involved in complex assemblies. Each treatment has its own characteristics that should be considered based on the ultimate goal and the target market.

Shot-peened steel is more durable because shot peening, as we’ve discussed, increases its robustness, in addition to improving its aesthetics. Therefore, this can be a process to consider not only for enhancing the product’s appearance but also to prepare it well for subsequent processing stages and enhance its durability over time.

Upon request, at Metal’s, we carry out shot peening treatments on stainless steel using glass or ceramic microspheres. This material, in particular, allows us to work on the product’s aesthetics while simultaneously enhancing the hardness and resistance of the material.

Of course, to achieve the desired result, factors such as the hardness of the material used for the spheres, their size, the speed, flow, and intensity of the jet must be taken into consideration.

Do you want to know more?

Discover the best stainless steel surface treatments for your project. Rely on our professionals and evaluate the benefits you can achieve in your processes.